UV is a cost-effective and energy-efficient thermal treatment alternative for preventing microbial growth in sugar syrups and sweeteners.

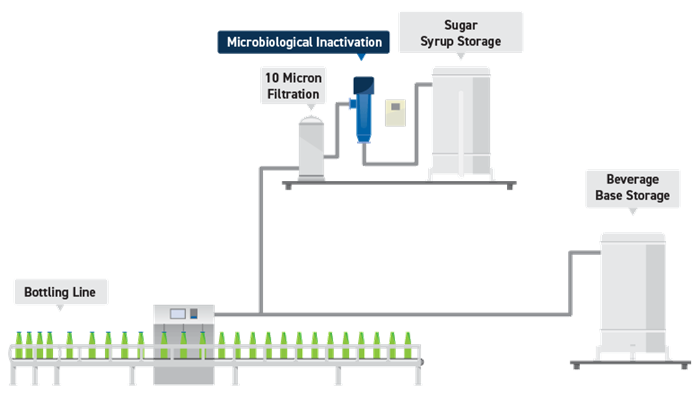

For food and beverage facilities seeking to improve the final product quality of sweetened beverages and meet stringent quality standards, UV (ultraviolet) treatment is an effective and economical solution. UV systems treat all known microorganisms* that lead to the spoilage of liquid sugar, such as yeasts, molds and spores. By preventing microbial growth, the quality of the sugar syrup is maintained, and its shelf-life is extended without the need for chemical additives and preservatives.

Extends shelf life

Extends shelf life

Reduces product waste

Reduces product waste

Maintains flavor and product quality

Maintains flavor and product quality

Reduces need for chemical additives or preservatives

Reduces need for chemical additives or preservatives

UV systems prevent microbial growth in sugar syrups through the UV inactivation process. When microorganisms are exposed to wavelengths of UV light, their DNA is damaged, and they are instantaneously rendered incapable of reproducing.

Many liquids can be effectively treated using UV, including cloudy or darker fluids with a UV Transmittance (UVT) as low as 20%. Our systems are optimized to treat these fluids by forcing the liquid to be exposed closer to the lamps for a longer period of time to receive higher doses of UV energy.

Microbiological inactivation with UV is a physical process that adds nothing to the fluid it is treating but UV light and therefore does not impact taste, odor and color. This is particularly beneficial when treating product water or sugar syrups for beverages. The speed and efficiency of the treatment process allow the footprint of UV systems in syrup rooms to be relatively small, making it ideal for both new plants and retrofits.

Minimal contact time required

Minimal contact time required

No impact to taste, odor, or color

No impact to taste, odor, or color

Compact system

Compact system

Easy to install

Easy to install

For those products that can tolerate the temperature, heat pasteurization may be an option to treat liquid sugar and sugar syrups. Although, thermal treatment has been known to be an energy-intensive process that can lead to the potential formation of possible carcinogens such as Hydroxymethylfurfural (5-HMF). As an alternative, UV can provide some significant benefits:

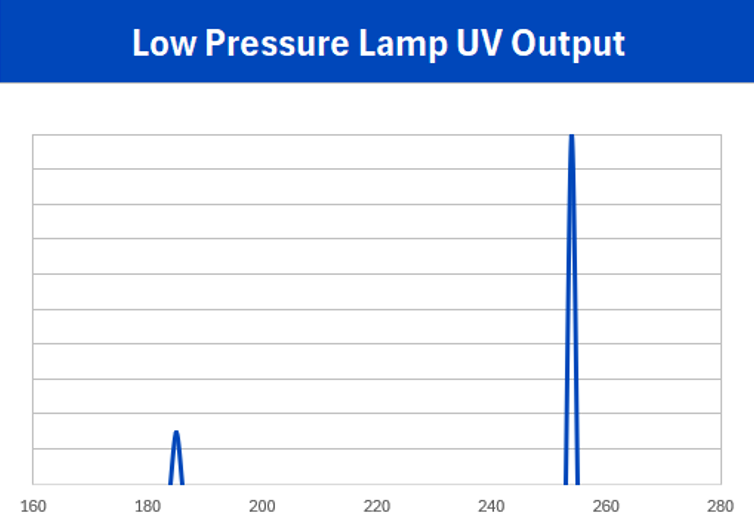

Aquafine UV systems use low-pressure high-output (LPHO) lamp technology. Our lamps can meet your log reduction requirements while saving you money.

While medium-pressure lamps are more powerful, their higher heat output, shorter lifetimes, and lower electrical efficiency make them less preferred for UV applications.

LPHO mercury lamps (LPHO) are ideal for UV applications because of their ability to generate targeted and effective emission wavelengths, 185 nm and 254 nm, with high efficiency.

Aquafine low-pressure TOC lamps emit both 185nm and 254nm wavelengths, effectively breaking down organic molecules while simultaneously inactivating any microbiological contaminants.

The European Framework Regulation (EC) 1935/2004 is a major regulation governing the safety and quality standards of the food and beverage industry. It ensures that all food contact materials (FCM) are safe and compliant with European Union (EU) legislation.

Our OptiVenn Series and Avant Series products are compliant with EC 1935/2004 for food and beverage manufacturing, including the treatment of liquid sugar. We take great care and pride in ensuring our products meet or exceed regulatory and compliance requirements for the regions and applications we serve.

Click below to learn more about (EC) 1935/2004 and why we prioritize complying with these regulations in the regions we serve while following good manufacturing practices.

Contact us today to speak to an expert.

Learn more about the advantages of UV for liquid sugar syrup treatment.

*Specific UV systems manufactured by Trojan Technologies have been validated through microbial testing. Through this testing, performance data has been generated for UV dose delivery to inactivate Escherichia coli (E. coli), fecal coliform, Poliovirus, Cryptosporidium, Giardia, and Adenovirus. For a detailed list of UV systems and target organisms, visit www.trojantechnologies.com/en/support/treatment-claims