Drinking water sources we rely upon every day are increasingly at risk of chemical contamination. Many of these contaminants have been proven harmful or carcinogenic and must be treated and removed in order for the water to be considered usable.

These contaminants may come directly from human sources such as industrial manufacturing, agricultural run-off and wastewater discharge, or they may originate from natural sources, such as the taste and odor-causing chemicals in water generated by algae and bacteria blooms.

The UV advanced oxidation process (also known as UV AOP) is an established technology for the remediation of contaminants in groundwater and surface water. Our systems have been installed around the world to treat a variety of contaminants.

Volatile Organic Compounds

Pesticides

By-products

Explosives

Hazardous Substances

Contaminant treatment utilizing UV AOP does not physically remove contaminants from the water like granulated activated carbon (GAC) does. Instead, UV light breaks chemical bonds to break down chemical contaminants in water.

A water treatment plant with GAC filters designed to remove environmental contaminants might need to consider incorporating a UV AOP system if 1,4-dioxane is eventually detected in GAC effluent.

The Merchantville-Pennsauken Water Commission approached Trojan Technologies for a 1,4-dioxane treatment solution. The TrojanUVFlex®AOP was chosen to address their 1,4-dioxane concerns.

More than 65 sites in Nassau County needed help addressing their unique treatment needs. The TrojanUVFlex®AOP was selected for what is now the world’s largest 1,4-dioxane treatment initiative.

The Leo J. Vander Lans Water Treatment Facility needed to address NDMA contamination in recycled water. The TrojanUVPhox® was chosen to minimize footprint and energy consumption.

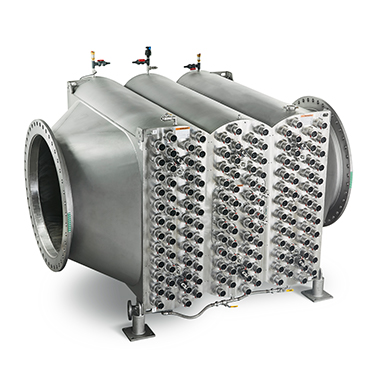

The TrojanUVFlex®AOP is our latest UV advanced oxidation solution for the treatment of contaminants. Its cross-flow lamp orientation enhances treatment efficiency and provides built-in redundancy. A compact and modular chamber design allows for easy expandability and installation in even the smallest of spaces.

The TrojanUVSwift®ECT provides year-round treatment for seasonal taste & odor events.

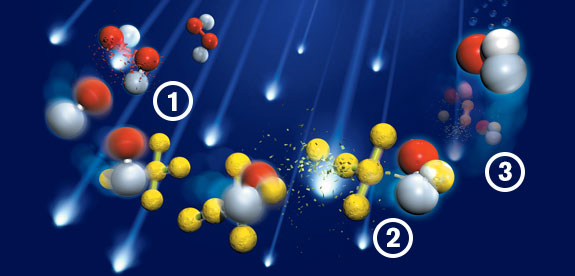

UV AOP uses ultraviolet light, alone or in combination with an oxidant, to break down chemical contaminants in water.

UV converts the oxidant (e.g., hydrogen peroxide) into highly reactive oxidizing radicals.

The oxidizing radicals attack and decompose contaminants.

At the same time, UV light treats the water.

Not all contaminants can be easily removed from water using processes like microfiltration, granular activated carbon or reverse osmosis. For contaminants such as 1,4-dioxane and certain nitrosamines, UV AOP is the only practical and proven solution.

Our UV AOP systems can also perform treatment to obtain log reduction credits for target organism inactivation*. This is ideal for water providers needing to meet requirements of the Surface Water Treatment Rule, Long Term 2 (LT2) Enhanced Surface Water Treatment Rule, or the Groundwater Rule, in addition to their contaminant removal needs.

Many other treatment technologies merely transfer the contaminant from one phase to another (e.g. air stripping: from water to air) resulting in a potentially hazardous, contaminant-laden residual that requires further treatment or disposal.

UV AOP occurs instantaneously within the UV chamber, eliminating the need for the large concrete contact basins or steel pipes commonly used in conjunction with ozone. This allows UV advanced oxidation systems to be easily retrofitted into existing water treatment facilities.

Our on-site Environmental Containment Treatment laboratory, run by our renowned team of scientists and researchers, has analyzed thousands of water samples from around the world.

We measure characteristics of your water critical to UV AOP performance – such as UV transmittance, pH, nitrate ion concentration, and radical scavenging – to determine if the technology makes sense for your plant. Then, we can design a robust UV AOP system specifically for your unique treatment needs, guaranteed to meet your contaminant removal requirements.

*Specific UV systems manufactured by Trojan Technologies have been validated through microbial testing. Through this testing, performance data has been generated for UV dose delivery to inactivate Escherichia coli (E. coli ), fecal coliform, Poliovirus, Cryptosporidium, Giardia, and Adenovirus. For a detailed list of UV systems and target organisms, visit www.trojantechnologies.com/support/treatment-claims

Have questions? Call us at 1 (888) 220-6118 or complete the form below.